Step 1: Pre-Wash

We start with a fresh batch of Lake City .223 military brass. To keep the machines clean and to make our first round of initial inspection a little easier, we give the brass a good bath and dry thoroughly.

Step 2: Inspection

For Clean Bright Shiny Brass, the first thing we do is give our Lake City Mitary Brass a BATH! Carefully tumble washing the brass helps keep our machinery in perfecIt’s important to find and eliminate pieces of brass that may cause trouble, so we do an initial inspection to clear out any rejects that may cause trouble later.

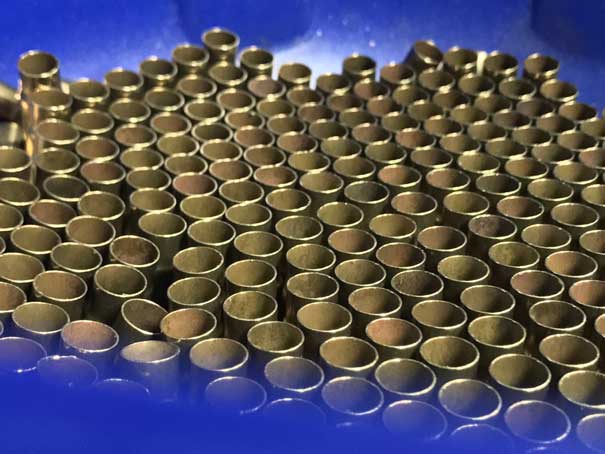

Step 3: De-priming / Swaging

Not only do we remove the old primers, but it is also very important to remove the crimp that the military puts on their brass. This step is very important so that your new primer is inserted properly and does not end up getting crushed and causing problems for you during reloading.

Step 4: Inspection

Occasionally, a primer makes it through the de-priming station, or worse, the primer “top” is removed, but the sides are still stuck in the bottom of the brass. This step looks to further remove any obstacles to a great reloading session at your home. Furthermore, we spot check brass with a special “go/no-go” primer hole gage to make sure the slot is just the right size for a new primer to be loaded up.

Step 5: Lube

The brass is now ready for a healthy coat of case lube. This ensures that the brass slides into the sizing die in a smooth and consistent manner for better accuracy during the trim.

Step 6: Size & Trim

This step will now re-size the shape of the brass to the perfect 300blackout form. It will also trim off the un-necessary brass down to 1.360 inch in length. This is well within the SAAMI specs, fits well, and leaves just a bit for future trim sessions if needed.

Step 7: Quick Clean

Here we do a quick cleanup of shavings left over from the trim process.

Step 8: Deep Clean

This time we take the brass for about a 3 to 4-hour wash with stainless-steel pins. This step not only gets the brass to a whole new level of clean and shine on the outside, but the stainless-steel pins also get deep inside the brass and even into the primer hole. Delaying the deep wash to this step maximizes the effectiveness of the deep clean process.

Step 9: Dry

After the cleaning, we use a couple of methods to make sure the brass gets nice and dry before continuing its journey.

Step 10: Polish

We use a special corn cob media to polish the brass. This higher grade, smaller size media works the best and does NOT get stuck in the small primer hole. This stage also does wonders at removing any potential burs from the trimming stage.

Step 11: Annealing

When done right, annealing extends brass life and makes neck tension more consistent, something very important for accuracy. Annealing is a “dark science” that you must get just right. We got the process worked in perfectly to our process. It’s an option for those who are really picky about their brass, but can be skipped to save money.

Step 12: Packaging & Shipping

All our brass is carefully counted by weight and we always throw in a little extra just to be sure. We shrink wrap our brass and load it up in priority mailer boxes. All our shipping is FREE. When you place your order, we will email you a tracking number and receipt.